PerformanceES500 series drivers can easily drive induction motors (asynchronous,permanent magnet synchronous motors) to meet the working requirements in various environments with high-performance current vector technology; while maintaining excellent performance and functions,from the perspective of customer applications,high Significant improvements have been made in reliability,ease of use,maintainability,environmental friendliness,installation space and design standards.

Performance

The latest generation of motor control special chips from German Infineon company is selected,and the international cutting-edge software and hardware technology is used to integrate the perfect drive output,and can provide remote online upgrade program services for high-end customers.

Supports multiple motor drives

Supports vector control of three-phase AC asynchronous motors,vector control of three-phase AC synchronous motors,and vector control of permanent magnet synchronous motors without position feedback.

Excellent PMSM control performance

Smooth and efficient drive permanent magnet synchronous motors (including permanent magnet synchronous motors without speed or rotor position sensors) to achieve higher energy efficiency; also can be used on low-speed control industrial equipment Enables direct drive for higher energy efficiency and better control performance.

Supports multiple control modes: speed mode,torque mode (open loop/closed loop),position mode.

Fast current limiting function

When the current exceeds the current protection point,the current can be quickly limited within the current protection point to avoid overcurrent alarms caused by sudden load or interference.

Unique rev tracking function

No special hardware detection circuit is required,and it can quickly track the rotation of the motor speed without any impact,especially suitable for: fans/water pumps,equipment that needs to track the speed,there are three speed tracking methods to choose from.

Overexcitation function

There is no need to add accessories such as peripheral braking resistors to achieve fast braking effect;

Improve product usability;

It can suppress the bus voltage rise during the deceleration process,avoid frequent overvoltage faults,and at the same time quickly brake to meet the needs of rapid shutdown.

Easy functionality

Instant stop function

This function means that in the event of an instantaneous power failure or a sudden drop in voltage,the inverter reduces the output speed,feeds back energy through the load,and compensates for the drop in voltage,so as to maintain the short-term operation of the drive. .

Industry application macro function

Industry application macro function is for the special requirements of performance functions in industrial applications,and realizes the one-key initialization function,which reduces the workload and technical requirements of front-line debugging personnel.

Support company ESDriverMS background software

Rich background monitoring functions are convenient for on-site data acquisition and debugging; support online oscilloscope function; support batch upload and download of parameters;

Can display U0 group parameters in real time,with monitoring and diagnostic functions; can automatically generate debugging documentation.

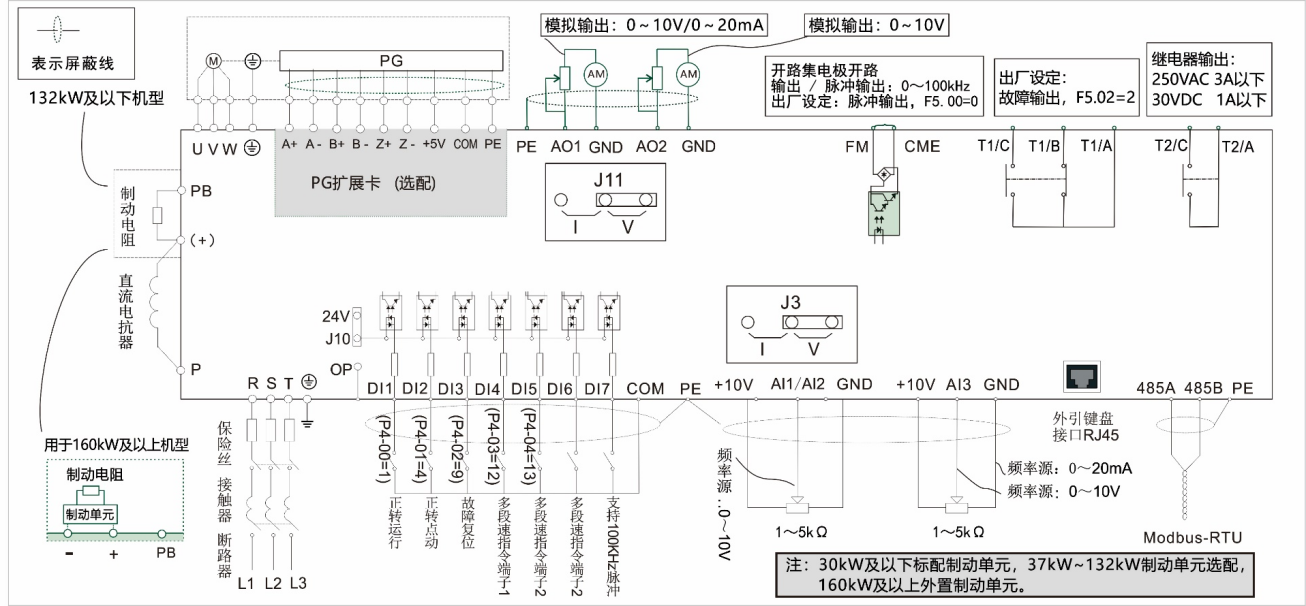

The terminal functions are flexible and diverse,making it easier to use

There are 51 kinds of multi-function terminals DI,42 kinds of DO,and 16 kinds of logic function options for AO,which meet the general control function requirements of general drives;

AI terminals can be flexibly selected as multi-functional DI terminals; AI1-AI3 can be set with 4-point broken lines and 5 kinds of curve correspondences respectively,supporting high-precision proofreading on site ;

Practical built-in 5 groups of virtual DI and DO function options,reducing external DI/DO wiring;

DI7 high-speed pulse input terminal and FM high-speed pulse output terminal support up to 100kHz pulse specification.

Built-in adaptive PID function module

There are two built-in PID parameter groups,which can be automatically switched according to deviation,DI terminal,and frequency conditions. There are various choices of given and feedback sources,which are rich in types and practical;< /span>

PID feedback loss detection function,convenient for user fault diagnosis function;

A group of PID factory default parameters for a specific industry can meet the equipment requirements,and it is suitable for printing packages,wire drawing machines,cables and other occasions where the coil diameter changes. Simplify the debugging process and facilitate maintenance.